We like lens flares (as opposed to Roger Deakins 🙂 However, flares can be a negative artifact/side effect on machine vision applications. A White paper titled “Eliminating Stray Light Image Artifacts via Invisible Image Sensor Coverglass” demonstrates how to mitigate lens flares with an Omnidirectional Anti-reflection (OAR) Nanotexturing Technology developed by Edgehog.

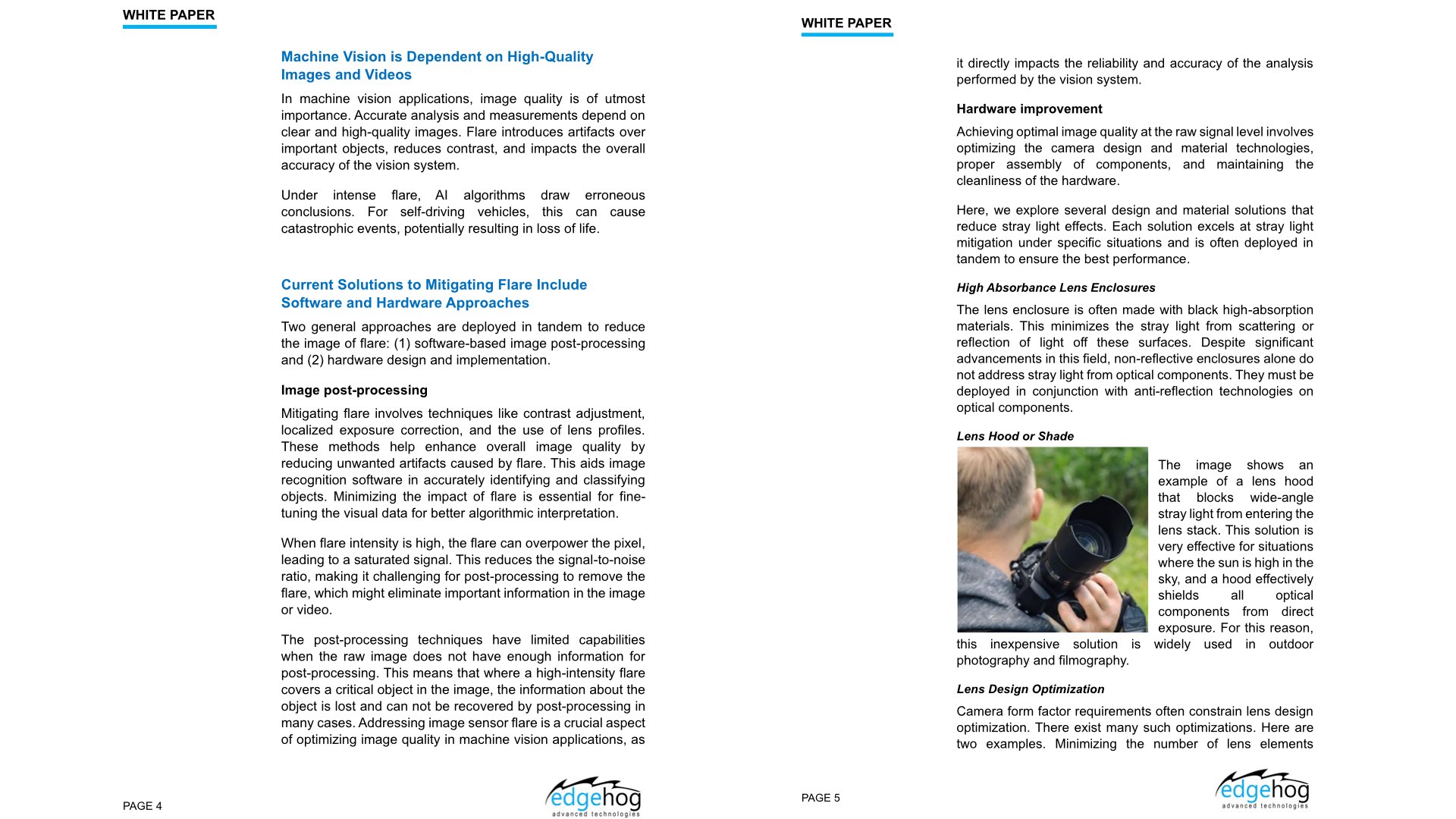

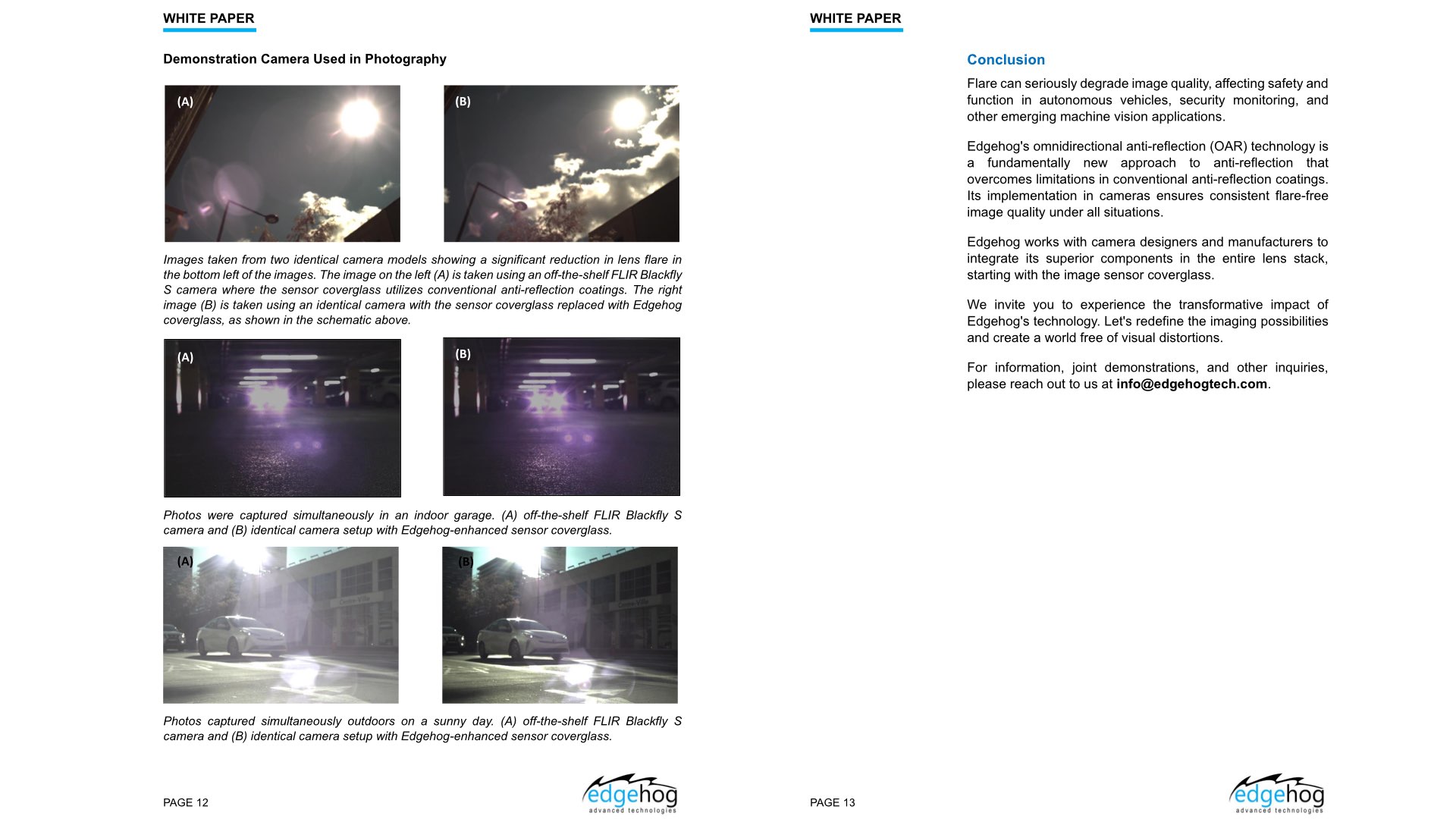

The white paper titled Eliminating Stray Light Image Artifacts via Invisible Image Sensor Coverglass, talks about two ‘cinematic components’ regarding light that are not desired on machine vision applications, but, on the other hand, can be very much desired by filmmakers. Those factors are scientifically defined as Stray light and Veiling flare. Stray light describes light in a camera that is not intended by the optical design. When stray light hits the image sensor, this causes undesirable optical artifacts in images, such as ghosting and flare. Veiling flare, also known as “flaring” and “veiling glare,” manifests as a haze that washes out the image and reduces contrast when a bright light source is shining on the lens, typically when the source of bright light is outside the photo. The paper adds that flares can significantly degrade the quality of images, washing out color contrast and creating distracting artifacts. That would be a disadvantage to machine vision applications.

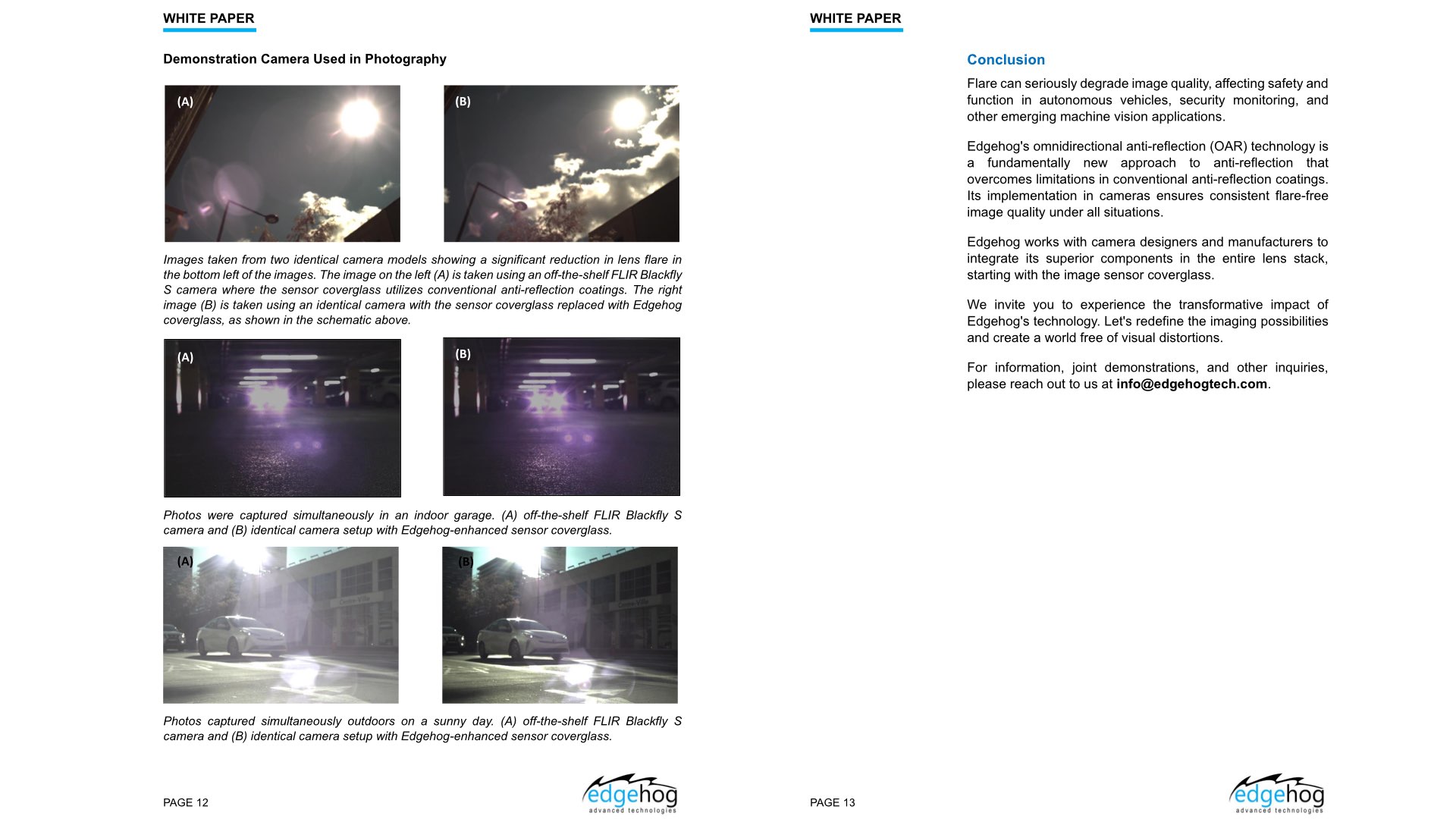

More interestingly, this is how ‘Lens Flares’ are scientifically defined in machine vision: “Lens flare, also known as ghosting and ghosting flare, manifests as clear, distinct visible spots in images, such as in the image above. Lens flare artifacts usually appear symmetrically opposite to the light source. Lens flare often occurs in the shape of the aperture, such as the hexagonal shape in the image above. Other shapes can include starbursts, rings, circles, or ovals—the location of the stray light changes with the position of the bright light source in the photo”.

As stated in the paper: “In machine vision applications, image quality is of utmost importance. Accurate analysis and measurements depend on clear and high-quality images. Flare introduces artifacts over important objects, reduces contrast, and impacts the overall accuracy of the vision system. Under intense flare, AI algorithms draw erroneous conclusions. For self-driving vehicles, this can cause catastrophic events, potentially resulting in loss of life”.

Lens flare, also known as ghosting and ghosting flare, manifests as clear, distinct visible spots in images, such as in the image above. Lens flare artifacts usually appear symmetrically opposite to the light source. Lens flare often occurs in the shape of the aperture, such as the hexagonal shape in the image above. Other shapes can include starbursts, rings, circles, or ovals—the location of the stray light changes with the position of the bright light source in the photo.

Edgehog is commercializing moth-eye 2.0 technology, a fundamentally different approach to creating anti-reflective surfaces. The approach involves creating nanotextures into the surface of the glass component. These nanotextures are smaller than the wavelength of light and create a fuzzy surface where light never meets a distinct abrupt border between the air and glass. Instead, the light experiences a gradual gradient in the index of refraction, allowing all wavelengths of light to pass through without any scattering. The result is an optical component with no reflection and no scattering, appearing as an invisible component that still bends or refracts light. Edgehog moth-eye structures are interconnected, creating components with excellent optical properties, and enhancing the structural integrity of these surfaces.

Watch the highlights of this article in the video below:

As a footnote, this white paper presents a technology that mitigates flares that can interfere with machine vision applications. That would be a very intriguing angle that shows the opposite approaches between machine vision to cinematography. Although many cinematographers can’t stand flares (see Deakins) and love their images sharp and clean. Nevertheless, utilizing Nanotexturing technology to reduce flares and light artifacts could be a valid solution even to cinema cameral. Don’t you think?

link